Qhov tseeb, cov no yog cov laj thawj hauv qab no:

1. Kev ua:

(1) Kev ua haujlwm siab dhau, kev kub ceev dhau, kev muab tub lim ntau dua, lub sijhawm txhaj tshuaj ntev ntev thiab tuav lub siab yuav ua rau muaj kev ntxhov siab ntau dhau thiab tawg.

(2) Kho cov pwm qhib ceev thiab siab los tiv thaiv cov khoom kom sai thiab quab yuam rub tawm ntawm pwm thiab tawg.

(3) Ua kom qhov kub ntawm cov pwm kom zoo kom cov khoom tuaj yeem tshem tau yooj yim ntawm pwm, thiab txo qhov kub ntawm cov khoom kom tsis txhob decomposition.

(4) Tiv thaiv kom tsis txhob tawg vim qhov vuam cov cim thiab cov yas degradation, ua rau txo cov neeg kho tshuab lub zog.

(5) Siv tus neeg sawv cev tso tawm tsim nyog thiab xyuas kom tshem tawm cov aerosols thiab lwm yam khoom uas adhering rau pwm nto nquag.

(6) Residual stress ntawm workpiece tuaj yeem raug tshem tawm los ntawm kev kho cua sov tam sim ntawd tom qab tsim los txo qhov tsim ntawm cov kab nrib pleb.

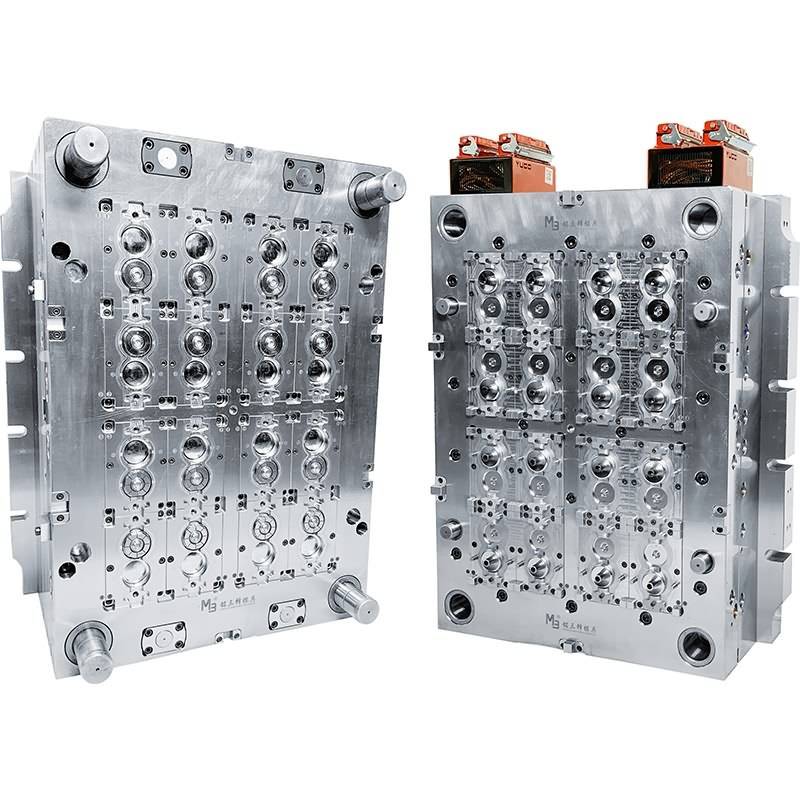

2. Pwm yam:

(1) Lub ejection yuav tsum sib npaug, xws li tus naj npawb thiab ntu ntu ntu ntawm lub ejector pins yuav tsum txaus, qhov inclination ntawm lub ejector yuav tsum txaus, thiab qhov chaw ntawm cov kab noj hniav yuav tsum du txaus kom tsis txhob tawg vim lub concentration ntawm ejection residual kev nyuaj siab vim sab nraud quab yuam.

(2) Cov qauv ua haujlwm yuav tsum tsis txhob nyias dhau, thiab qhov kev hloov pauv yuav tsum muaj kev hloov pauv ntawm lub voj voog kom ntau li ntau tau kom tsis txhob muaj kev ntxhov siab los ntawm cov ces kaum ntse thiab chamfers.

(3) Txo qhov kev siv cov hlau ntxig kom tsis txhob muaj qhov nce hauv kev ntxhov siab vim qhov sib txawv shrinkage ntawm cov ntxig thiab cov khoom ua haujlwm.

(4) Rau qhov tob hauv qab, qhov tsim nyog demoulding cua inlets yuav tsum tau muab los tiv thaiv kev tsim ntawm lub tshuab nqus tsev tsis zoo.

(5) Lub ntsiab channel yog txaus rau lub rooj vag khoom yuav tsum demoulded yog hais tias nws tsis harden yav tom ntej kom nws yuav yooj yim demoulded.

(6) Kev sib txuas ntawm sprue bushing thiab lub nozzle yuav tsum tiv thaiv cov khoom siv tawv tawv los ntawm kev kos rau hauv thiab ib feem ntawm cov pwm ruaj khov.

3. Khoom siv:

(1) Cov ntsiab lus ntawm cov khoom siv rov ua dua tshiab yog siab dhau, ua rau cov khoom tsis muaj zog.

(2) Cov av noo siab dhau lawm, ua rau qee cov khoom siv tshuaj lom neeg nrog dej vapor, txo lub zog thiab ua rau ejection tawg.

(3) Cov khoom siv nws tus kheej tsis haum rau qhov nruab nrab yuav tsum ua tiav, lossis nws qhov tsis zoo, thiab yog tias nws muaj kab mob, nws yuav tawg.

4. Tshuab yam:

Kev ua haujlwm ntawm lub tshuab plasticizing yuav tsum tsim nyog.Yog tias nws me dhau lawm, lub peev xwm plasticizing yuav tsis sib xyaw thiab ua nkig.Yog tias nws loj heev, nws yuav mob heev.

Post lub sij hawm: Sep-11-2023